About cvt

About cvt

Blog Article

อาจให้ความรู้สึกในการควบคุมการขับขี่ที่ดีกว่าด้วยการปรับเปลี่ยนเกียร์ขึ้นลงเป็นสเต็ป

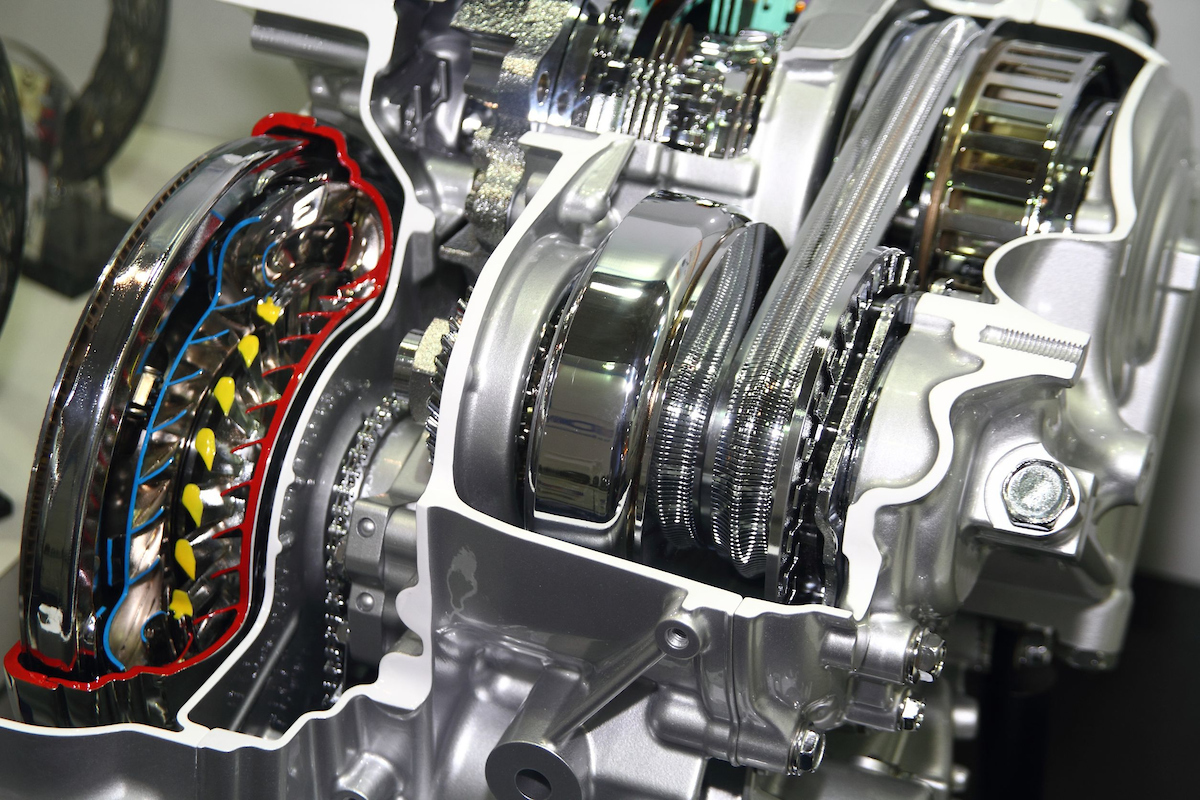

In a standard CVT, there is an input pulley that may be connected to the engine crankshaft by way of a torque converter (or clutch pack) and an output pulley that sends electric power on the wheels. A belt (or chain) connects The 2 pulleys, which may change their diameters to supply an infinite amount of gear ratios. With no gears, the stepless transmission permits smoother acceleration and effectiveness, even though being lesser in sizing in comparison to transmissions that do have gears. This can be a very good list of qualities for Daihatsu, mainly because it allows for much better packaging in its kei and compact vehicles. But there are actually downsides to a standard CVT

Some drill presses and milling devices have an easy belt-drive CVT procedure to regulate the speed with the chuck, such as the Jet models J-A5816 and J-A5818.[forty nine] In this system, the helpful diameter of just the output shaft pulleys is continuously variable. The input pulley linked to the motor is usually fastened in diameter (or from time to time with discrete steps to permit a array of pace ranges).

Naturally, autos (and bikes) have much more than two gears to permit straightforward working at a wide array of speeds. The inner workings of a gearbox are pretty intricate, with many cogs, shafts and rods that make up the gears the system to change in between them.

Concurrently with this motion of input pulley, feeding output pulley (sheave) also moves and go clear of the preset pulley which consequently moves the Element of the v-shaped belt wrapped throughout the output pulleys in the direction of the reduce cross-sectional A part of the conical output pulleys and sought after speed ratio is attained.

By comparison, a constantly variable transmission is a study in simplicity. Most CVTs have only a few standard elements:

Better cost. For the specified degree of electric power-transmitting potential, a hydrostatic CVT are going to be costlier to generate than an equivalent geared transmission. In addition to the pump and motor(s), a hydrostatic process demands using an oil reservoir, piping and in many programs, an oil cooler, this previous product staying essential to dissipate the waste heat that outcomes from hydrostatic power transmission's rather very low effectiveness.

“After i check out more CVT from the start it’s just like a new born toddler. The infant is growing — and when the baby grows it will deliver. There are actually fruits! They may advantage different persons.”

체인/벨트와 풀리의 마찰에 의존하지 않고 유압펌프와 모터를 이용해 동력분배를 한다. 특성상 유압을 이용하기에 높은 토크를 견뎌낼 수 있는 것은 장점이나 구조상 생산단가가 높고 세심한 정비가 필요한데다가 변속비가 제한적이고 빠른 변속이 힘든 것이 단점.

Whilst CVTs have quite a few Rewards, they even have some likely drawbacks. Such as, some drivers may perhaps realize that The dearth of unique equipment shifts might make it tricky to decide how the vehicle is executing, and Other folks might locate the engine sound to be much more noticeable than with a conventional transmission.

“In a the latest stop by I built to Ethiopia, I had been ready to begin to see the treatment that goes into an enlargement challenge like this,” stated Dr. Simon Adams, CVT president and CEO. “Being able to establish a fresh trauma-targeted rehabilitative care center in Ethiopia throughout a time of armed conflict is often a remarkable accomplishment.

Some makers have designed CVTs with ‘move’ technology to mimic the gears of a traditional automatic gearbox. Audi provided this system all through the early 2000s, and an identical technological innovation can be found in modern day Subaru designs.

If torque converter, then perodua could be in the appropriate way. Even though Toyota CVT with 1st Bodily equipment appears to be more tempting.

You gained’t be able to explain to a CVT or computerized car just by watching the shifter or equipment change console. The Operating ideas of the CVT go further than that.